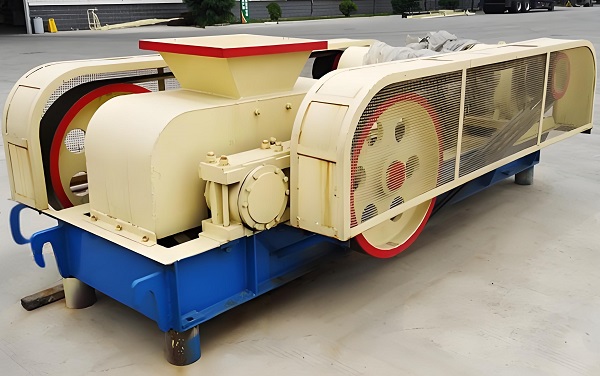

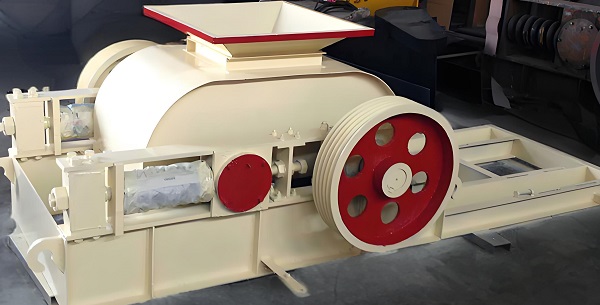

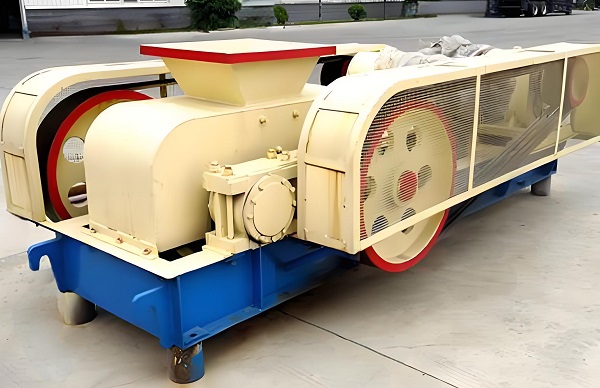

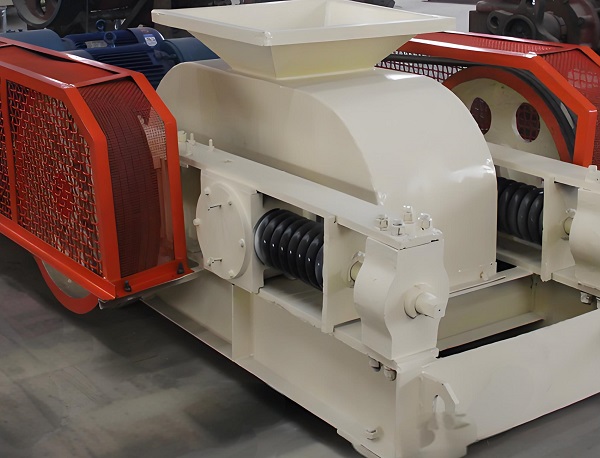

In industrial production and resource processing, crushing is a core step in material pre-processing, directly impacting subsequent processing efficiency, product quality, and resource utilization. The double-roll crusher, a classic extrusion-type crushing device, boasts advantages such as simple structure, high crushing efficiency, and precise particle size control. It is widely used in industries such as mining, building materials, chemicals, and waste recycling. It uses a pair of counter-rotating rollers to generate squeezing and shearing forces to crush materials. It can meet both coarse and medium-to-fine crushing requirements, making it a key piece of equipment driving efficient production processes across various industries.

The Core Functions of the Double-Roll Crusher

The double-roll crusher's functions revolve around efficient crushing and precise particle size control. Through its unique structural design and operating principle, it solves the crushing challenges of various materials, laying the foundation for subsequent production processes. This can be categorized into four core aspects:

1. Material Volume Reduction, Reducing Handling and Transportation Costs

In many industries, raw materials or waste are initially large and have low density, which not only takes up a lot of storage space but also increases transportation costs. Double-roll crushers significantly reduce material volume and density by squeezing and crushing materials, reducing subsequent handling and transportation burdens. For example, in the coal industry, mined raw coal often contains large gangue and lumps of coal, resulting in significant volume disparity. Direct transportation of raw coal results in low railcar utilization and is prone to scattering during transport. Double-roll crushers can crush raw coal and gangue to uniform particle sizes (e.g., 50-100mm), resulting in denser packing. This increases railcar filling efficiency by 30%-40%, reduces transport frequency, and reduces transportation costs per ton by 15%-20%. In solid waste management, large waste items such as used tires and plastic barrels can be reduced to 1/5-1/10 of their original size after crushing in a double-roll crusher. This not only saves landfill space but also facilitates subsequent recycling (such as tire pyrolysis and plastic recycling).

2. Precisely control output particle size to meet diverse production needs. Different industries have significantly different requirements for crushed material particle size. Double-roll crushers precisely control the output particle size by adjusting the gap between the two rollers, ranging from a few millimeters to several hundred millimeters. The output particle size is uniform, with a pass rate exceeding 95%. In the building materials industry, limestone must be crushed to a particle size of 20-30mm for cement production to ensure efficiency in the subsequent grinding process and cement quality. Concrete aggregate production, on the other hand, requires crushing to 5-16mm (fine aggregate) or 16-31.5mm (coarse aggregate), depending on the intended use. Double-roll crushers can quickly adjust the gap between the rollers to meet varying particle size requirements without having to replace core components, significantly enhancing production flexibility. In the chemical industry, fertilizer raw materials (such as phosphate rock and potash) must be crushed to a fine particle size of 1-5mm to ensure sufficient chemical reactions. The precise particle control capabilities of a double-roll crusher ensure uniform particle size, preventing incomplete reactions due to particle size variations, and improving the purity and yield of the fertilizer product.

3. Combining crushing and shaping to enhance material utilization

During the crushing process, some materials require not only particle size reduction but also a regular particle shape to enhance subsequent processing or application. The extrusion crushing method of a double-roll crusher achieves the dual effects of "crushing + shaping." In metal mining, blasting of iron ore, copper ore, and other materials produces irregular lumps. Directly grinding these lumps in a ball mill results in low grinding efficiency and increased energy consumption. When crushing ore, a double-roll crusher uses the squeezing action of its two rollers to break irregular lumps into relatively regular cubic particles, reducing the content of needle-like and flake-like particles (typically controlled to below 10%). This improves ore grinding efficiency, increases the ball mill's throughput by 15%-20%, and reduces steel ball loss during the grinding process. In the production of construction sand, natural sand resources are becoming increasingly scarce, and manufactured sand has become a major alternative. Double-roll crushers can crush and shape rocks such as granite and basalt, producing manufactured sand with uniform particle size and good particle shape, meeting the grading requirements for construction sand. The finished sand has superior compressive strength and durability compared to products produced by traditional crushing equipment.

4. Adapts to diverse materials and solves complex crushing challenges. Industrial production involves a wide range of materials, from hard ores and metals to brittle glass and ceramics, and even sticky coal and sewage sludge. Double-roll crushers optimize roller material, surface structure, and speed design to adapt to the crushing needs of materials with diverse characteristics, solving the problems of easy clogging and wear associated with traditional crushing equipment. For hard materials (such as granite and iron ore, with a Mohs hardness of 6-8), the rollers of a double-roll crusher are made of high-manganese steel or wear-resistant alloy, with a surface hardening treatment to reach a hardness of HRC55-60. This allows them to withstand the impact and friction of the material and prevent excessive wear of the roller surface. For sticky materials (such as coal slime and municipal sludge), the roller surface can be designed with a toothed or grooved roller structure to increase friction between the material and the roller surface. Adjustable roller speed and gap prevent material from sticking to the roller surface and clogging. For brittle materials (such as glass and ceramic fragments), the double-roll crusher uses low speed and large gap crushing parameters to avoid over-crushing, reduce fines, and improve material recovery.

Industry Application Scenarios of Double-Roll Crusher

Due to its diverse functions and excellent adaptability, the double-roll crusher has established mature application solutions in multiple industries and has become an indispensable key equipment in various industry production processes. The following analysis will be based on specific industry scenarios.

1. Mining Industry: Core Equipment for Primary and Secondary Ore Crushing

The mining industry is one of the primary applications of double-roll crushers. Whether it's metal ores (iron, copper, gold, silver) or non-metallic ores (limestone, gypsum, quartz sand), all require crushing equipment to reduce the mined ore (typically 500-1500mm in particle size) to a particle size suitable for subsequent processing. Double-roll crushers play a vital role in both primary and secondary ore crushing.

In metal mining, for example, iron ore mined from open pits or underground mines is first crushed to 200-300mm using primary crushing equipment (such as a jaw crusher). It then enters a double-roll crusher for secondary crushing, reducing the ore to 50-100mm before being fed into a ball mill for grinding. The advantage of a double-roll crusher is that it produces minimal fines during the crushing process, reducing ore loss during transportation and storage. Furthermore, the uniform particle size improves ball mill grinding efficiency and reduces energy consumption. In gold mining, gold-bearing ore often coexists with gangue, requiring crushing to separate the gold particles from the gangue. The gentle crushing of a double-roll crusher prevents over-crushing and loss of gold particles, improving gold recovery by 5%-8% compared to traditional cone crushers.

In non-metallic mineral processing, limestone, a core raw material for cement and lime production, has a direct impact on subsequent production efficiency due to its crushing quality. A double-roll crusher can crush large limestone (800-1200mm in diameter) to a uniform particle size of 20-50mm, eliminating over-crushing. The crushed material can be directly fed into a rotary kiln for calcination, reducing the burden on subsequent grinding processes and lowering overall energy consumption in cement production lines by 10%-15%. For gypsum ore, a double-roll crusher enables low-temperature crushing of gypsum (which dehydrates and deteriorates easily at high temperatures). By controlling the temperature rise during the crushing process (typically no more than 30°C), the quality of the gypsum is guaranteed, providing high-quality raw material for the production of products such as gypsum board and gypsum mortar.

2. Building Materials Industry: Key Pretreatment Equipment for Concrete, Cement, and Sand Making

The building materials industry has stringent requirements for material particle size and morphology. Double-roll crushers, with their precise particle size control and excellent shaping, are widely used in concrete aggregate production, cement raw material crushing, and manufactured sand preparation.

In concrete aggregate production, traditional crushing equipment (such as impact crushers) produces aggregates with a high content of needle-like and flake-like particles, which affects the concrete's workability and compressive strength. Double-roll crushers, through the squeezing action of two rollers, crush rocks (such as limestone and granite) into cubic particles, keeping the needle-like and flake-like particle content below 8%, meeting the national standard for construction aggregates (GB/T 14685-2022). For example, after a large concrete mixing plant introduced a double-roll crusher, the aggregate produced was used in C60 high-performance concrete, which increased the concrete's 28-day compressive strength by 12%. This improved workability, reduced the amount of admixtures used, and lowered concrete production costs. In cement production, double-roll crushers are primarily used for crushing cement clinker and homogenizing the finished cement product. After calcining in a rotary kiln, cement clinker reaches a high temperature and high hardness. Traditional crushing equipment is susceptible to component damage due to high temperatures and impact. However, the rollers of a double-roll crusher are made of high-temperature and wear-resistant materials to withstand the high temperatures (≤300°C) and impacts of the clinker, crushing the clinker to 5-10mm particles, facilitating subsequent cooling and grinding. Furthermore, before storage of the finished cement product, the double-roll crusher can break up any clumping, ensuring a uniform particle size and preventing agglomeration from affecting its performance.

In manufactured sand production, double-roll crushers can replace traditional impact sand making machines for hard rock such as granite and basalt. The manufactured sand produced by these crushers has a continuous gradation, and its fineness modulus can be flexibly controlled by adjusting the roller gap (typically 2.3-3.0). The rough surface of the particles facilitates bonding with the cement paste, enhancing the strength of the concrete. A manufactured sand production company uses basalt manufactured sand produced by a double-roll crusher for highway pavement base construction. Testing shows that the pavement base achieves a compaction degree of over 98%, meets design requirements for flexural strength, and produces minimal dust, meeting environmental requirements.

3. Chemical Industry: High-Efficiency Equipment for Raw Material Pretreatment and Waste Disposal

The chemical industry's production processes involve a variety of chemical raw materials and waste. Some raw materials must be crushed to a fine particle size to ensure adequate reaction, while some waste must be recycled or disposed of after crushing. Double-roll crushers, with their ability to accommodate diverse materials, play an important role in the chemical industry.

In fertilizer production, crushing raw materials such as phosphate rock, potash, and ammonium chloride is a key pretreatment step. As the primary raw material for producing diammonium phosphate and superphosphate, phosphate rock must be crushed to a fine particle size of 1-3mm to increase contact area with sulfuric acid and improve reaction conversion. Double-roll crushers precisely crush phosphate rock to the desired particle size by adjusting the roller gap and speed. The crushing process is metal-free (the rollers are made of ceramic or wear-resistant alloy), ensuring the purity of the fertilizer product. After introducing a double-roll crusher, a fertilizer plant increased its phosphate rock conversion rate by 8% and diammonium phosphate production by 10%. It also reduced sulfuric acid consumption and lowered production costs.

In the coal chemical industry, double-roll crushers are primarily used for coal crushing and gangue recycling. Coal, as a raw material for coal chemical processing, must be crushed to a particle size of 5-20mm to ensure stable combustion in gasifiers or boilers. The toothed roller structure of a double-roll crusher effectively crushes coal, preventing excessive fines from being generated during the crushing process and reducing dust emissions during combustion. Furthermore, the double-roll crusher can crush gangue (a byproduct of coal mining) into 30-50mm pieces for use in the production of building materials such as gangue bricks and concrete blocks, effectively reusing the gangue as a resource and reducing the amount of solid waste destined for landfill.

In chemical waste treatment, double-roll crushers are used to crush discarded catalysts, plastic barrels, and glass containers. Waste catalysts often contain precious metals (such as platinum and palladium), which require crushing for precious metal extraction. The gentle crushing of a double-roll crusher prevents loss of precious metals due to excessive crushing, thereby increasing extraction efficiency. For discarded plastic barrels and glass containers, the double-roll crusher can reduce them to small pieces, facilitating subsequent recycling or harmless disposal, thereby reducing environmental pollution.

4. Waste Recycling Industry: A Pre-treatment Tool for Solid Waste Resource Utilization

With rising environmental awareness, the waste recycling industry is rapidly developing. Double-roll crushers, as core equipment for solid waste crushing, are widely used in recycling plastics, metals, electronic waste, construction waste, and other materials, providing pre-treatment support for waste resource utilization.

In plastic waste recycling, double-roll crushers are used for coarse crushing of used plastic bottles, plastic film, and plastic pipes. Waste plastics are typically large and irregular in shape, requiring initial crushing into smaller pieces (20-50mm) before entering a fine crusher for further crushing. Double-roll crushers can be designed with either smooth or grooved rollers. Smooth rollers are suitable for crushing hard plastics (such as PVC pipes), while grooved rollers are suitable for crushing soft plastics (such as PE film) to prevent sticking and clogging during the crushing process. For example, a plastics recycling company uses a double-roll crusher to coarsely shred used PET bottles. The resulting plastic chunks are uniform in size, increasing processing efficiency by 25% before entering the fine crusher. This also reduces wear on the fine crusher's cutters and lowers maintenance costs.

In metal waste recycling, double-roll crushers are used to crush and sort scrap steel and non-ferrous metals (copper and aluminum). Scrap steel (such as scrapped car hulls and rebar) is reduced in size after being crushed by a double-roll crusher, making it easier to transport and smelt. Furthermore, the crushing process removes impurities such as paint and rust from the steel surface, improving the purity of the recycled steel. For scrap aluminum products (such as aluminum pots and aluminum profiles), the low-speed crushing method of a double-roll crusher prevents aluminum oxidation during the crushing process, reducing metal loss. The crushed aluminum chunks can then be directly fed into a smelting furnace, achieving an aluminum recovery rate exceeding 98%.

In electronic waste recycling, double-roll crushers are primarily used for coarse crushing of used circuit boards, mobile phone casings, and computer motherboards. Electronic waste is a complex material, containing a variety of materials, including metals, plastics, and glass. It must first be crushed into small pieces (10-30mm) before being separated into its various components using subsequent sorting equipment (such as magnetic separation, eddy current separation, and air flow separation). The sealed design of the double-roll crusher prevents the escape of dust and harmful gases generated during the crushing process, complying with environmental standards. Furthermore, its gentle crushing method prevents over-crushing of precious metals (gold and silver) in circuit boards, thereby improving precious metal recovery efficiency.

In construction waste recycling, double-roll crushers are used to crush concrete blocks, bricks, and tiles to produce recycled aggregate. After primary crushing in a jaw crusher, the construction waste enters a double-roll crusher for secondary crushing, reducing the material to 5-31.5mm recycled aggregate for use in the production of concrete blocks, roadbed fillers, and permeable bricks. The recycled aggregate produced by a double-roll crusher boasts uniform particle size and low impurity content (controllable to below 3%). A construction waste treatment plant uses this recycled aggregate for municipal roadbed construction. Testing has shown that the roadbed's bearing capacity meets design requirements, and the production cost per ton of recycled aggregate is 50 yuan lower than that of natural aggregate, achieving a win-win situation for both economic and environmental benefits.

Double-roll crushers, with their "efficient crushing, precise particle control, adaptability to multiple materials, and easy maintenance and environmental friendliness," play an irreplaceable role in a variety of industries, including mining, building materials, chemicals, and waste recycling. With the continuous advancement of industrial technology, double-roll crushers will further optimize their structural design.

Design (such as the use of intelligent control systems to automatically adjust the roller gap and speed) and improve wear resistance (such as the use of new composite material roller surfaces) provide stronger support for efficient production and green development in various industries.

Save Time! Get A Detailed Quotation Quickly.