Introduction: RDF, as an innovative and sustainable way of waste treatment and energy utilization, has broad application prospects. With the continuous advancement of technology and the support of policies, RDF will play an increasingly important role in environmental protection, energy and economy, and contribute to the realization of sustainable development goals. The performance of RDF mainly refers to a series of characteristics and capabilities it possesses as a fuel. The following are the factors that affect the performance of RDF:

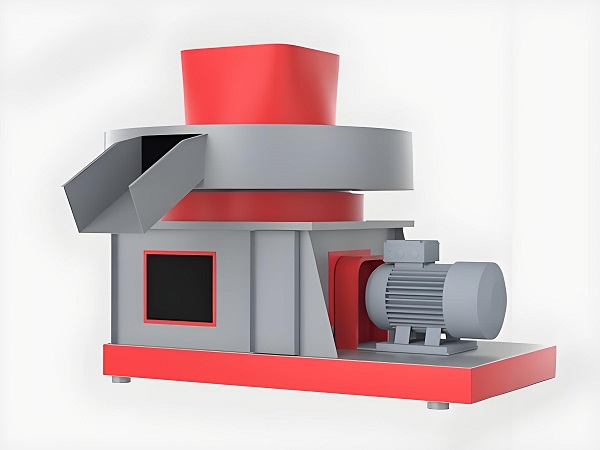

RDF Rod Making Machine

1. RDF raw material composition:

Raw material calorific value: Raw material calorific value is one of the key characteristics that affect the performance of RDF. If the raw material calorific value is too low, the combustion performance of RDF will be poor, and it may have an adverse effect on the life of the combustion equipment and pollutant control. According to the minimum standard of calorific value of garbage that can be directly incinerated, the calorific value of RDF should be at least 5000kJ/kg.

Raw material ash: RDF raw material ash mainly refers to inorganic non-combustibles. If the ash content is too high, it will not only affect the combustion calorific value and combustion performance of RDF, but also increase the amount of ash treatment after combustion, thereby reducing the life of the burner and increasing operating costs.

Raw material moisture: During the combustion process, the evaporation of moisture will absorb the corresponding heat, so the higher the raw material moisture, the lower the RDF calorific value. At the same time, when the raw material moisture content is low, the formability is better, and the RDF fuel rods are long and smooth. Therefore, the moisture content of the original garbage cannot be too high, otherwise the pretreatment drying process will consume too much energy to meet the moisture content requirements.

2. The effect of additives (calcium content) on RDF performance:

The increase in additives (calcium content) will increase the density of RDF (this is mainly because the density of the additive Ca(OH)2 is greater than that of the original garbage), and the solid sulfur and solid chlorine effects are obvious, which can curb the production of dioxins and reduce NOx; it has little effect on the formability of RDF, but the adverse effect is to reduce the calorific value of RDF.

RDF Rod Making Machine

3. The effect of coal blending on RDF performance:

In order to increase the calorific value of RDF, a certain amount of coal can be added before it is formed. Adding some coal can not only increase the strength of RDF, but also be beneficial to the storage, transportation and use of RDF. The combustion of RDF mixed with coal can greatly reduce the content of SO2, NOx and dioxins in the exhaust gas. In addition, the greater the proportion of coal blending, the smaller the amount of excess air required. However, after reaching a certain coal ratio, the increase in RDF strength will tend to be flat.

4. The influence of molding pressure on RDF performance:

The RDF raw material compacting process will have an important impact on the strength of the RDF finished product, and its important parameter is the molding pressure. The density of RDF increases with the increase of molding pressure (this is mainly due to the increase in pressure, which leads to an increase in the density between the garbage and the additive). At the same time, the increase in molding pressure makes RDF have the maximum drop strength, so there is an optimal molding pressure, which is related to the content of elastic components such as plastics and rubber and the amount of coal blending. However, increasing the molding pressure will increase power consumption and have an adverse effect on the combustion characteristics of RDF.

5. Types and treatment methods of garbage:

Different types of garbage release different amounts of heat when burned, and different treatment methods will also affect the calorific value of the fuel rods. For example, the calorific value of RDF fuel rods is one of the important indicators of its performance. The higher the calorific value, the greater the heat released during combustion, and the higher the power generation efficiency.

6. Manufacturing process of RDF fuel rods:

Due to different manufacturing processes of fuel rods, the density and composition of fuel rods will also be different, which will affect the calorific value and other performance indicators of fuel rods, such as ash, volatile matter, fixed carbon, etc. These indicators will also affect the combustion performance and power generation efficiency of fuel rods.

RDF Rod Making Machine

7. Environmental factors:

In actual applications, environmental factors such as changes in temperature and humidity will also affect the performance of RDF. Changes in temperature will directly affect the adsorption performance and activity of the catalyst, and increases in humidity will cause the catalyst surface to adsorb water vapor, thereby reducing its catalytic activity.

8. Catalyst quality issues:

The initial quality of the catalyst, the uniformity of particle size, the surface smoothness, and the attenuation problems that may occur during operation, such as particle wear and loss of active ingredients, will affect the performance of RDF.

PS: The factors affecting the performance of RDF mainly include raw material composition, additives, coal content and molding pressure. When selecting and using RDF, these factors need to be considered comprehensively to ensure that its performance and quality meet the requirements. In practical applications, these factors need to be considered comprehensively to optimize the performance and combustion effect of RDF.

Save Time! Get A Detailed Quotation Quickly.