In modern industrial production, iron impurities are a key threat to equipment safety and reduced product quality. Iron separators, as core equipment for material purification and equipment protection, are widely used in various industries such as coal, ore, grain, and chemicals. Traditional iron separators suffer from drawbacks such as insufficient magnetic field strength, poor adaptability, and high maintenance costs, making it difficult to meet the demands of intelligent and efficient production. With innovations in rare earth permanent magnets and automated control technologies, iron separators have achieved breakthrough upgrades in structural design. This article focuses on the core structural advantages and functional characteristics of iron separators, deeply analyzing the design highlights of the magnetic field generation, load-bearing transmission, and iron unloading structures, providing technical reference for industry practitioners and helping production lines improve quality and efficiency.

Core Structural Advantages of Iron Separators

As a key piece of equipment for material purification and equipment protection, the structural design of iron separators directly determines their iron removal efficiency and stability. The core advantages are concentrated in the following three aspects:

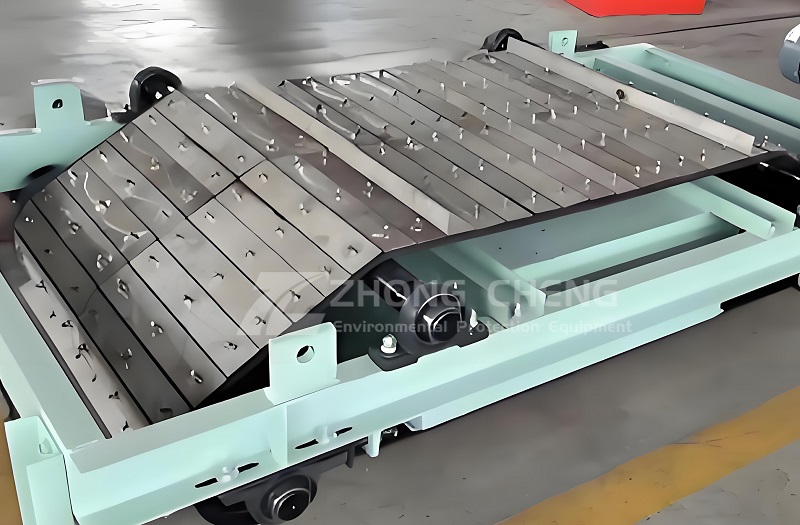

1. Optimized Design of the Magnetic Field Generation Unit The magnetic field generation unit is the core component of the iron separator. Mainstream equipment adopts a combination structure of "rare earth permanent magnets + magnetic guide plates," which has significant advantages. Rare-earth permanent magnets (such as neodymium iron boron) are arranged in a modular fashion, forming a closed magnetic field loop through a polarity-alternating design. The magnetic field strength can reach 12000-18000 Gs, increasing the magnetic field density by more than 30% compared to traditional electromagnetic coil structures. The magnetic guide plate is made of low-carbon steel or silicon steel sheets, precision-machined and tightly bonded to the permanent magnets, enhancing the magnetic field focusing effect and reducing magnetic field leakage, ensuring that the effective iron removal area is concentrated on the material conveying path. Furthermore, some high-end equipment adopts a segmented magnetic circuit design, allowing adjustment of the magnetic field strength of each segment according to material thickness and flow rate, adapting to different working conditions and solving the problems of single magnetic field strength and poor adaptability in traditional iron separators.

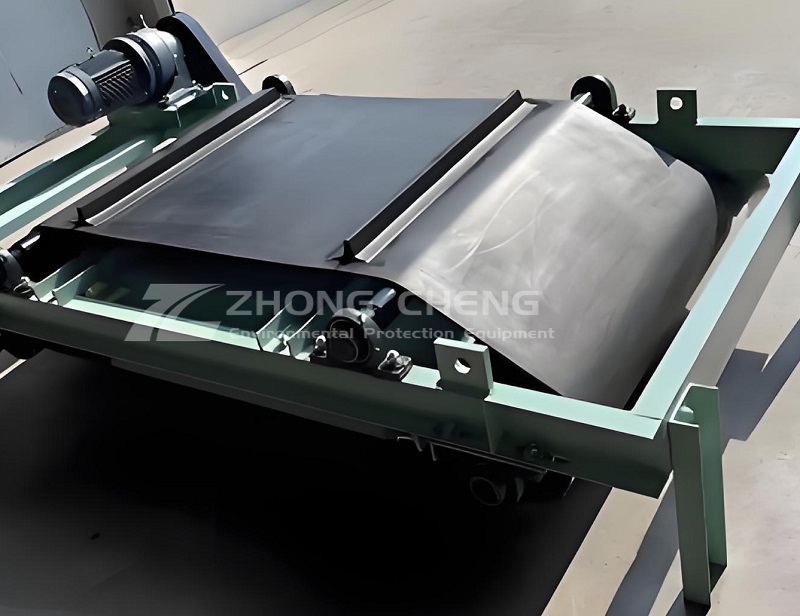

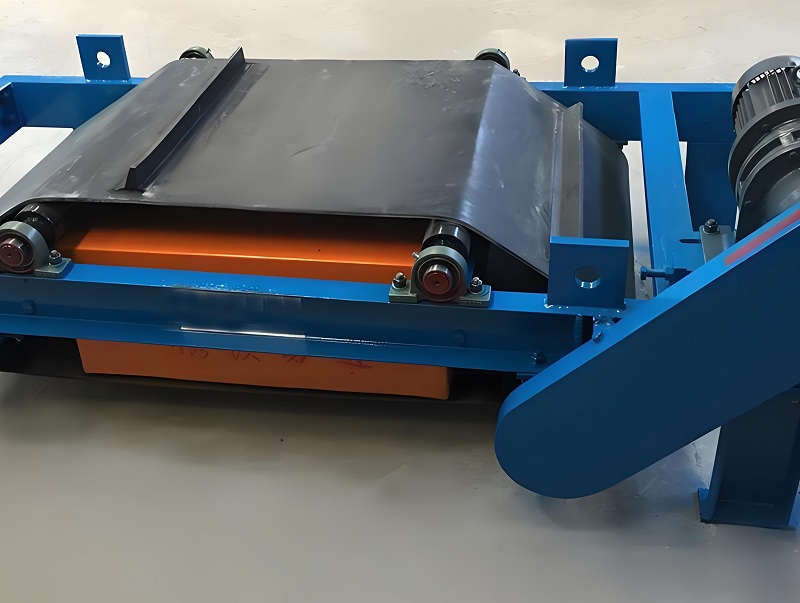

2. Stability Design of Load-Bearing and Transmission Structures For the high-intensity, long-term operation requirements in industrial scenarios, the load-bearing structure of the iron separator is welded from high-strength steel. The body undergoes aging treatment to eliminate internal stress, resulting in strong resistance to deformation. Taking a belt-type magnetic separator as an example, its transmission structure adopts a combination of "motor + reducer + synchronous belt". The motor is a variable frequency speed control model, which can precisely adjust the operating speed of the magnetic separator according to the material conveying speed to achieve synchronous iron removal. The reducer adopts a hardened tooth surface design, with a transmission efficiency of over 95% and a service life 2-3 times longer than ordinary reducers. Meanwhile, the roller surface is wrapped with wear-resistant rubber, which enhances the friction with the conveyor belt, prevents material scratches, and reduces maintenance costs. For suspended magnetic separators, the suspension structure is equipped with a spring buffer device, which can absorb the vibration caused by material impact, reduce damage to the machine body and mounting brackets, and ensure long-term stable operation of the equipment.

3. Convenient Design of Iron Unloading Structure Iron unloading efficiency directly affects the continuous working capacity of the magnetic separator. Modern magnetic separators adopt various convenient iron unloading structures. Manual iron separators are equipped with a flip-up magnetic core or a drawer-type magnetic plate, allowing operators to quickly clean adsorbed iron impurities without disassembling the equipment, saving time and effort. Automatic iron separators utilize structures such as electromagnetic chuck power-off release, scraper removal, or automatic unloading by a drum-type magnetic separator to achieve continuous 24-hour iron unloading without manual intervention. Some devices also feature a dual iron unloading structure to ensure thorough removal of iron impurities and prevent residues from affecting the iron removal effect.

Core Functional Features of Iron Separators

The characteristics of iron separators are not only reflected in their structural design but also in their performance in practical applications, mainly including the following:

1. High Iron Removal Efficiency and Strong Adaptability Thanks to the optimized magnetic field structure, iron separators can effectively adsorb iron impurities of different particle sizes. Whether it's large iron pieces with a diameter greater than 5mm or iron powder and shavings with a particle size less than 0.1mm, efficient separation can be achieved, with an iron removal rate of over 98%. Meanwhile, the equipment is adaptable to various material conveying scenarios, such as belt conveyors, screw conveyors, and pipeline conveyors. For different materials such as coal, ore, grain, and cement, different types of iron removal methods can be selected, including dry iron removal, wet iron removal, or strong magnetic iron removal, to meet diverse iron removal needs. For example, in the coal industry, a permanent magnet drum separator can be directly installed at the head of the belt conveyor to automatically separate iron impurities from the coal; in the grain processing industry, a suspended iron separator can be suspended above the conveying pipeline to remove impurities such as iron nails and wires from the grain, ensuring the safety of the processing equipment.

2. Stable and reliable operation, low maintenance cost. The structural design of the iron separator fully considers the complexity of the industrial environment. The body adopts a sealed design, which is waterproof, dustproof, and corrosion-resistant, and can adapt to harsh working conditions such as high temperature, humidity, and high dust levels, with a service life of 8-10 years. Permanent magnet separators require no external power supply, relying solely on permanent magnets to generate a magnetic field, resulting in extremely low energy consumption and noiseless, vibration-free operation. Electromagnetic separators are equipped with overload and temperature protection devices to prevent damage from voltage fluctuations or prolonged operation. In terms of maintenance, key components utilize standardized designs for easy replacement; routine maintenance only requires periodic cleaning of the magnetic plates and checking the lubrication of transmission components, making maintenance costs significantly lower than traditional iron removal equipment.

3. Outstanding Safety Performance, Protecting Downstream Equipment One of the core functions of iron separators is to protect downstream processing equipment, such as crushers, grinders, and conveyors, preventing iron impurities from entering and causing jamming, wear, or even damage. Safety protection devices, such as anti-detachment structures for magnetic plates and anti-blockage designs for unloading channels, effectively prevent iron impurities from splashing or accumulating and causing safety accidents. Furthermore, some high-end iron separators also feature intelligent monitoring functions, using sensors to monitor parameters such as magnetic field strength and iron removal volume in real time. In case of magnetic field attenuation or equipment malfunction, alarm signals can be issued promptly to remind operators to perform maintenance, ensuring safe and stable operation of the equipment.

4. Easy Installation and Simple Operation The magnetic separator's structural design prioritizes practicality, featuring a compact size and moderate weight. It can be flexibly installed according to site space, whether ground-mounted, suspended, or integrated into the production line, allowing for rapid deployment. Operationally, manual magnetic separators require only simple flipping and pulling actions to unload iron; automatic magnetic separators utilize a PLC control system for automated operation. Operators can set operating parameters and monitor equipment status in real time via the control panel, requiring no specialized skills. Some models also support remote control, facilitating centralized management of multiple magnetic separators from a central control room, thus improving production efficiency.

Synergistic Advantages of Structure and Features

The structural advantages and functional features of the magnetic separator mutually support each other, creating a synergistic effect where "structure determines performance, and performance highlights features." The optimized magnetic field structure provides the foundation for high iron removal efficiency, the stable load-bearing and transmission structure ensures long-term reliable operation, and the convenient iron unloading structure enhances the equipment's continuous working capacity. Furthermore, the efficient, stable, and safe functional features further highlight the scientific and rational nature of the structural design. In practical applications, this synergistic advantage enables magnetic separators to not only meet single iron removal needs but also integrate into the entire production line, becoming key equipment for improving production efficiency, ensuring product quality, and reducing operating costs.

Magnetic separators play an irreplaceable role in industrial production due to their optimized magnetic field structure, stable load-bearing transmission design, convenient iron unloading method, and efficient, reliable, safe, and easy-to-operate features. With the continuous development of rare earth permanent magnet technology and automation control technology, the structure of magnetic separators will be further optimized, and their characteristics will become more prominent, providing stronger support for material purification and equipment protection in various industries.

The core of the technological upgrade of magnetic separators lies in the optimization of structural design and the synergistic improvement of functions. The modular design of the magnetic field generating unit, the stability upgrade of the load-bearing transmission structure, and the convenient innovation of the iron unloading structure jointly construct its core advantages of high efficiency and reliability. Modern magnetic separators not only achieve a high iron removal rate of over 98% but also possess outstanding features such as strong adaptability, stable operation, low maintenance costs, and convenient operation, effectively solving the industry pain points of traditional equipment. In the future, with the integration of intelligent and green technologies, iron separators will continue to make breakthroughs in areas such as precise magnetic field control and remote operation and maintenance, providing more solid equipment support for the high-quality development of various industries.

Save Time! Get A Detailed Quotation Quickly.