Preface: The ballistic screen is a device commonly used for solid particle screening and liquid-solid separation. As an efficient screening device, the ballistic screen mainly achieves material screening and separation through vibration and screen design. The ballistic screen has the advantages of high screening efficiency, strong adaptability, reduced blockage and intelligent control. It can quickly finely screen the material to meet various particle size requirements. The following is the working principle and function of the ballistic screen introduced by the editor of Zhongcheng Machinery:

A. Working principle of the ballistic screen

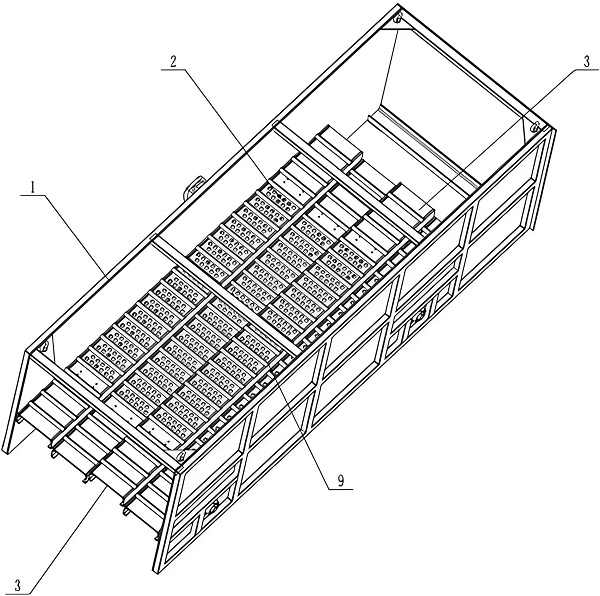

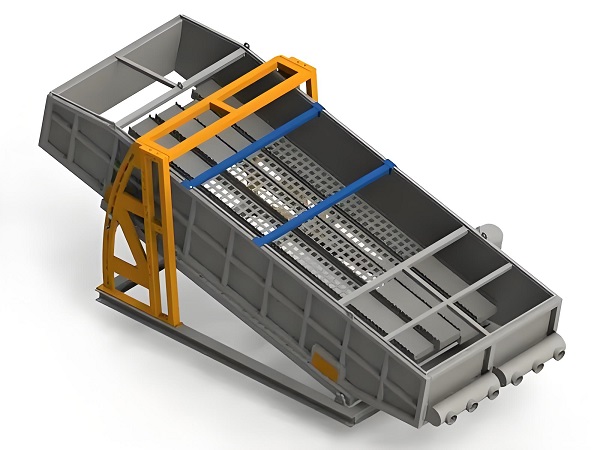

Ballistic Screen

The working principle of the ballistic screen is based on the periodic vibration force generated by the vibrator, which makes the material in the screen box bounce on the screen, thereby realizing the separation of particles of different sizes.

1. Basic composition: The ballistic screen is mainly composed of a screen box, a screen, a vibrator (or a vibration motor), a support device, a feed port and a discharge port.

2. Vibration generation: The vibrator (or a vibration motor) generates periodic vibration force to make the screen box vibrate in the vertical and horizontal directions. This vibration is achieved by driving the screen plate to move up and down and forward and backward through an eccentric shaft.

3. Material screening: The material enters the screen box through the feed port and is screened under the bouncing action on the screen. Specifically, when the material enters the screen box, due to the effect of vibration, the material presents a flow state in the screen box. Larger particle materials are blocked by the screen and cannot pass through the screen aperture, while smaller particle materials can fall through the screen aperture. During the screening process, the material 4. collides with the screen constantly, and is affected by the vibration force, bounces, and is evenly sprayed onto the screen surface above the screen bed at a certain angle, and then passes through the screen forward.

5. Influencing factors: The screening effect of the ballistic screen is affected by many factors, including the particle size and shape of the material, the interaction between the material and the screen aperture, the surface tension, density, humidity and viscosity of the material. For example, the greater the surface tension, the stronger the bouncing effect of the material on the screen; the greater the humidity, the stronger the adhesion of the material, which may affect the screening effect.

Ballistic Screen

B. Function of the ballistic screen

1. High screening efficiency: The ballistic screen can quickly separate materials of different sizes through high-speed vibration and screen design, which improves the screening efficiency.

2. Strong adaptability: The ballistic screen is suitable for screening various types of materials, whether it is wet garbage or dry garbage, it can maintain a good screening effect. At the same time, the multi-stage screen design can meet the screening needs of materials of different particle sizes.

3. Reduce blockage: The jumping movement of the ballistic screen can effectively reduce the adhesion and blockage of the material to the screen, and extend the service life of the equipment.

4. Intelligent control: Some advanced ballistic screens are equipped with intelligent control systems, which can monitor the operating status of the equipment in real time, and automatically adjust the vibration frequency and amplitude according to the material conditions, further improving the screening effect.

C. Application scenarios of the ballistic screen

The ballistic screen is widely used in many fields, especially in the field of garbage disposal. It can be used for preliminary screening of construction waste, decoration waste, etc., to remove larger debris; to classify and screen organic and inorganic waste; to finely screen recyclable materials such as waste plastics and waste metals; and to perform the final screening of waste to be landfilled to remove large particles that are not suitable for landfill.

Ballistic Screen

PS: With its unique working principle and high efficiency, intelligence and strong adaptability, the ballistic screen has a wide range of application prospects in the field of solid particle screening and liquid-solid separation, providing strong support for material processing in various industries.

Save Time! Get A Detailed Quotation Quickly.