As a kind of magnetic separation equipment widely used in industrial production, the main function of iron remover is to remove ferromagnetic impurities from materials, so as to improve product quality, protect production equipment and reduce operating costs. The following is a detailed description of the features and advantages of the iron remover. The content may exceed 2000 words, but the subject will be introduced as comprehensively and in depth as possible.

A. Basic features of iron remover

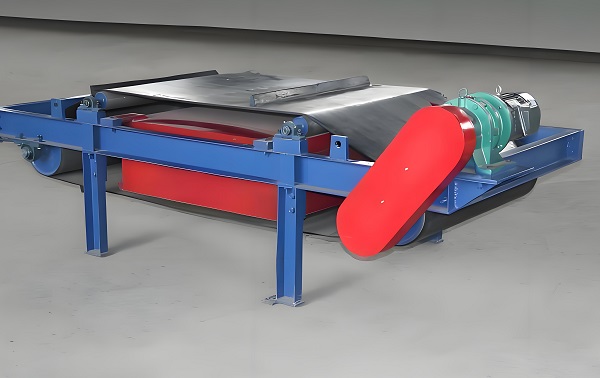

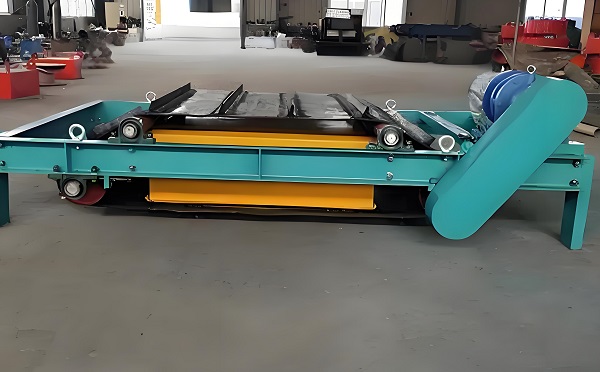

Iron Remover

Wide application range

The iron remover can work in various harsh environments, such as high temperature, low temperature, moisture, dust, etc., showing its strong adaptability and stability.

Whether solid materials or liquid materials, the iron remover can effectively remove the ferromagnetic impurities therein.

The magnetic source is stable and reliable

The magnetic source of iron remover usually adopts high performance permanent magnet or electromagnet, which is strong and stable in magnetism and can maintain high efficiency iron removal effect for a long time.

Permanent magnet does not need external power supply, reducing energy consumption and fault point, while electromagnetic iron can adjust the magnetic field intensity according to the needs, with higher flexibility.

Long service life

The design of the iron remover generally considers the long-term use requirements, and the wear-resistant and anti-corrosion materials are used to extend the service life of the equipment.

Regular maintenance can further extend the service life of the separator and reduce the frequency and cost of equipment replacement.

Easy iron removal

The iron remover is usually equipped with an automatic iron unloading device, which can conveniently remove the ferromagnetic impurities adsorbed on the equipment and reduce the complexity and labor intensity of manual operation.

Some iron removers also have remote control and automatic monitoring functions, which can monitor the iron removal effect and equipment status in real time and improve the production efficiency.

B. Features and advantages of electromagnetic separator

Iron Remover

Electromagnetic iron remover is an important type of iron remover. It generates magnetic field based on electromagnetic principle to absorb and remove ferromagnetic impurities in materials. The following are the features and advantages of electromagnetic separator:

The magnetic field intensity is adjustable

The magnetic field intensity of electromagnetic iron remover can be adjusted according to the actual needs to adapt to different materials and iron removal requirements.

The iron removal efficiency and precision can be easily controlled by adjusting the magnetic field intensity to meet diversified production requirements.

High iron removal efficiency

The magnetic field produced by electromagnetic iron remover is strong and stable, which can effectively remove ferromagnetic impurities in materials, including fine and deeply buried magnetic impurities.

Efficient iron removal helps to improve product quality and production efficiency, and reduce equipment failures and downtime caused by ferromagnetic impurities.

High degree of automation

Electromagnetic separator is usually equipped with automatic control system, which can realize remote control and automatic monitoring functions.

The automatic control system can monitor the iron removal effect and equipment status in real time, give alarm and handle abnormal conditions in time, and improve the stability and reliability of the production line.

Compact structure and small floor area

Space utilization and aesthetics are generally considered in the design of electromagnetic separator, which is compact in structure and small in floor area.

This makes the arrangement of electromagnetic separator on the production line more flexible and convenient, and reduces the requirements on the production site.

Easy maintenance

The maintenance of electromagnetic iron remover is relatively simple. Generally, it only needs regular inspection and cleaning of ferromagnetic impurities on the equipment.

Some electromagnetic iron removers also have self-diagnosis function, which can automatically detect the operation state and fault condition of the equipment, so as to facilitate the maintenance personnel to quickly repair and replace the parts.

Diversified cooling modes

Electromagnetic separator usually adopts multiple cooling methods to reduce coil temperature and ensure stable performance of equipment.

Common cooling methods include natural cooling, fan cooling and transformer oil circulation cooling. These cooling modes have their own advantages and disadvantages, which can be selected according to the actual use environment.

C. Features and advantages of permanent magnetic separator

Iron Remover

Permanent magnet iron remover is another common type of iron remover, which uses the magnetic field generated by permanent magnet to remove ferromagnetic impurities in materials. The following are the characteristics and advantages of the permanent magnetic separator:

Energy conservation and environmental protection

No external power supply is required for the permanent magnet iron remover, so the operation cost is low and energy conservation and environmental protection are required.

This makes the permanent magnet iron remover have obvious advantages in energy consumption and environmental pollution.

Simple structure and few faults

The permanent magnetic separator is simple and compact in structure, with few fault points and easy to maintain.

This reduces the maintenance cost and downtime of the equipment and improves the stability and reliability of the production line.

Long service life

The permanent magnet of the permanent magnet iron remover is usually made of high performance magnetic materials, which has a long service life.

This enables the permanent magnet iron remover to maintain a stable iron removal effect and equipment performance in long-term use.

Small floor area

Space utilization and aesthetics are taken into consideration in the design of permanent magnet iron remover, which usually covers a small area.

This makes the arrangement of the permanent magnetic separator on the production line more flexible and convenient, and reduces the requirements on the production site.

D. Application case and effect analysis of iron remover

Iron Remover

The following are some application cases and effect analysis of iron remover in different industries:

Chemical industry

In the chemical industry, raw materials and semi-finished products often contain various ferromagnetic impurities. If these impurities are not treated, the purity and quality of the product will be seriously affected.

The installation of pipe iron remover can effectively remove ferromagnetic impurities in liquid materials and improve the purity and quality stability of products.

At the same time, the pipe iron remover also has the advantages of compact structure, easy installation and maintenance, reducing the operating cost and maintenance difficulty of the chemical plant.

Power industry

In the power industry, coal and other fuels often contain ferromagnetic impurities. These impurities will produce a large amount of slag and dust during combustion, causing serious wear and corrosion to the boiler and power generation equipment.

Electromagnetic separator or permanent magnetic separator can effectively remove ferromagnetic impurities in fuel and reduce abrasion and corrosion of boiler and power generation equipment.

This not only improves power generation efficiency and quality stability, but also prolongs equipment life and reduces maintenance costs.

Food industry

In the food industry, ferromagnetic impurities can have a serious impact on the taste, quality and safety of products.

Iron remover (such as electromagnetic iron remover or permanent magnetic iron remover) can effectively remove ferromagnetic impurities in food raw materials and processing process.

This improves the purity and safety of food and protects the health and rights of consumers.

Metallurgical industry

In the metallurgical industry, ferromagnetic impurities are often contained in ores and wastes generated during smelting.

These ferromagnetic impurities can be effectively recovered and utilized by installing electromagnetic separator or permanent magnetic separator.

This not only improves the utilization rate of resources and economic benefits, but also reduces environmental pollution and ecological damage.

E. Future development trend of iron remover

Iron Remover

With the continuous progress of industrial technology and the development of intelligence, the iron remover will develop towards a more intelligent and automatic direction. The future separator will have the following characteristics:

Real-time monitoring and intelligent control

In the future, the iron remover will be able to monitor the content and types of ferromagnetic impurities in the materials in real time, and automatically adjust the working parameters according to the actual needs.

This will improve the accuracy and efficiency of iron removal and reduce the complexity and labor intensity of manual operation.

Remote monitoring and maintenance

In the future, the electromagnetic separator will have remote monitoring and maintenance functions, which can monitor the operation status and fault of the equipment in real time.

This will allow maintenance personnel to quickly repair and replace components, reducing equipment downtime and maintenance costs.

Efficient energy conservation and environmental protection

In the future, the iron remover will pay more attention to the research and development and application of high efficiency, energy conservation and environmental protection performance.

By using advanced materials and processes, the energy consumption and emission of the equipment are reduced, and the pollution and damage to the environment are reduced.

Iron Remover

Multi-function and integration

In the future, the iron remover will have multiple functions and integrated design, which can remove various impurities and pollutants in the materials at the same time.

This will improve the overall performance and utilization of the equipment and reduce the production cost and energy consumption.

PS: As an important magnetic separation equipment, the iron remover has a wide application prospect and important value in industrial production. Its characteristics and advantages include wide application range, stable and reliable magnetic source, long service life, convenient iron removal, etc; Different types of iron removers (such as electromagnetic iron remover and permanent magnetic iron remover) also have their own unique characteristics and advantages. With the continuous progress of industrial technology and intelligent development, the future iron remover will develop towards a more intelligent and automatic direction to provide more efficient, energy-saving and environmental protection iron removal solutions for industrial production.

Save Time! Get A Detailed Quotation Quickly.