Analysis of Mainstream Equipment and Application Characteristics for Municipal Solid Waste Screening

Municipal solid waste is characterized by its complex composition (30%-60% kitchen waste, 10%-20% plastic, 5%-15% paper, mixed with impurities such as bricks, stones, and metals), high moisture content (20%-40%), and tendency to stick together. Screening, as a core pre-processing step in the resource recovery and harmless treatment of waste, requires specialized equipment to classify materials and separate impurities, providing pre-treatment guarantees for subsequent incineration, landfill, and recycling. Currently, commonly used municipal solid waste screening machines mainly include five categories: drum screens, vibrating screens, air separators, bouncing screens, and disc screens. Each type of equipment is based on different separation principles and is adapted to different processing scenarios and material characteristics. This article will systematically analyze the technical characteristics, application scenarios, and practical points of each type of equipment, providing selection references for municipal solid waste treatment projects.

Rotary Cylinder Screen: Core Equipment for Large-Scale Municipal Solid Waste Screening

The rotary cylinder screen is a standard piece of equipment in municipal solid waste treatment lines. It achieves material grading through the rotation of a cylindrical screen, suitable for large-scale centralized municipal solid waste treatment plants (daily processing capacity of 500 tons or more). It can separate mixed waste into components of different particle sizes (e.g., >80mm, 40-80mm, 20-40mm, <20mm).

Its working principle is as follows: The screen cylinder is installed at an inclined angle (3°-5°), and has internal lifting plates. During rotation, the lifting plates lift and drop the material. Material smaller than the screen openings passes through the screen and is discharged, while material larger than the screen openings exits from the end of the screen cylinder. The core advantages are threefold: First, high processing capacity, with a single unit capable of handling 50-300 tons/hour, meeting the needs of large-scale processing; second, strong adaptability, with screen apertures customizable to meet requirements (5-100mm), able to withstand the impact of hard impurities such as bricks and glass in municipal solid waste, and not easily clogged; third, stable operation, with a simple structure, low failure rate, and a sealed design that reduces dust pollution.

A typical application scenario is the pretreatment stage of municipal solid waste incineration power plants. For example, a large incineration plant uses a Φ3.2×7m drum screen to process 1500 tons of municipal solid waste per day. Large impurities >80mm (such as furniture fragments and bricks) are separated and processed separately, combustible components (plastics, paper) of 20-80mm are fed into the incinerator, and fine materials <20mm (kitchen waste, dust) are utilized separately, achieving a screening efficiency of over 85%. It is important to note that when processing waste with high moisture content, a cleaning device (such as a brush or scraper) should be installed inside the screen cylinder to prevent material from sticking to the screen holes.

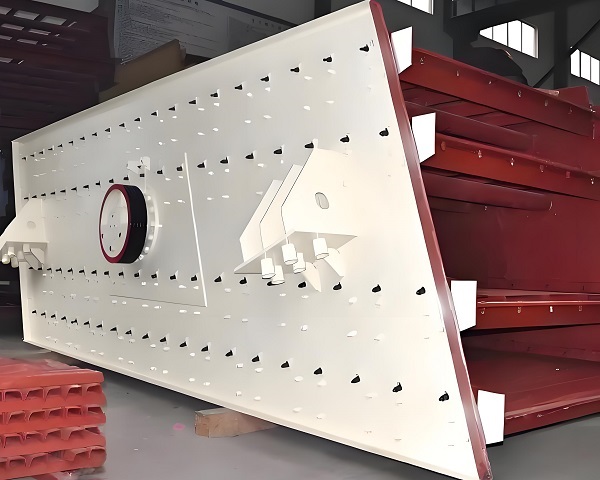

2. Vibrating Screen: A Fine Screening Option for Small and Medium-Sized Projects

Vibrating screens utilize high-frequency vibration generated by a vibrating motor to cause materials to bounce and move on the screen surface, achieving separation of coarse and fine materials. They are suitable for small and medium-sized municipal solid waste treatment projects (daily processing capacity 100-500 tons), and are particularly adept at separating waste components with low viscosity.

Depending on the vibration method, common types include linear vibrating screens and circular vibrating screens: Linear vibrating screens have a linear screen surface, resulting in fast material processing speed and are suitable for grading; circular vibrating screens have a circular screen surface, resulting in higher screening accuracy and the ability to separate fine-particle materials (such as <10mm kitchen waste). The core advantages include: First, high screening accuracy; by adjusting the vibration frequency (15-60Hz) and amplitude (1-5mm), the grading particle size can be precisely controlled, achieving a separation efficiency of over 90%. Second, compact structure; the footprint is only 1/3 to 1/2 that of a drum screen, making it suitable for projects with limited space. Third, convenient maintenance; the screen adopts a quick-release design, requiring only 30 minutes to 1 hour for replacement.

A county-level municipal solid waste transfer station uses a ZS-1848 linear vibrating screen, processing 300 tons of waste per day. It separates mixed waste into three grades: >40mm, 20-40mm, and <20mm. Kitchen waste (<20mm) is sent to the composting system, while combustible waste (20-40mm) is compressed and transported to the incineration plant, significantly improving waste processing efficiency. Its limitation lies in its tendency to clog pores when processing highly viscous, high-moisture waste, requiring the use of a spray or heating device.

3. Air Separator: Key Equipment for Separating Light and Heavy Materials

Air separators, based on differences in material density, use airflow to separate light materials (plastics, paper, foam) from heavy materials (bricks, metals, glass) in municipal solid waste. They are core equipment for waste recycling and are often used in conjunction with drum screens and vibrating screens.

Based on airflow direction, air separators are mainly divided into horizontal and vertical air separators: horizontal air separators blow air horizontally and are suitable for separating larger particle sizes of light materials; vertical air separators (also known as air separation towers) blow air upwards, resulting in higher separation accuracy and handling finer particle sizes of light materials. Their core advantages are: firstly, excellent separation effect, effectively separating materials with a density difference ≥0.2g/cm³, with a light material recovery rate of over 95%; secondly, wide adaptability, capable of handling various types of municipal solid waste with a moisture content ≤30%, regardless of material shape; and thirdly, low energy consumption, with a single unit powering only 5-15kW, resulting in operating costs far lower than other separation equipment.

A waste recycling plant uses a vertical air separator in conjunction with a drum screen to create a combined "screening + air separation" process. First, impurities larger than 50mm are separated by the drum screen. Then, the remaining material is fed into the air separator. The separated plastics and paper are packaged and recycled, while heavier materials are sent to landfills. The annual value of recycled resources exceeds 2 million yuan. When using this system, it is important to control the airflow speed (10-25m/s). Too high a speed can easily entrain heavy materials, while too slow a speed will result in incomplete separation of lighter materials.

4. Bounce Screen: High-Efficiency Separation Equipment for Kitchen Waste and Inert Materials

The bounce screen (also known as an elastic screen) uses an eccentric shaft to drive the screen plate in a high-frequency bouncing motion, utilizing the elasticity difference of the materials to achieve separation. It is particularly suitable for separating kitchen waste from inert materials (bricks, glass, metal) in municipal solid waste and is a core pre-treatment device for the resource recovery of kitchen waste.

Its working principle is as follows: the screen plate is tilted, and during high-frequency bouncing, inert materials with poor elasticity and high density slide on the screen plate and are discharged from the end of the screen plate; kitchen waste with good elasticity and low density (including some organic matter) bounces with the screen plate and leaks out through the screen holes. Its core advantages include: firstly, strong targeting, with a kitchen waste separation efficiency of 80%-85%, far exceeding ordinary screening equipment; secondly, good anti-clogging performance, the bouncing motion of the screen plate can self-clean up adhering materials, suitable for high-moisture waste with a moisture content of 30%-40%; and thirdly, flexible grading, adaptable to the processing needs of different waste components by adjusting the screen plate bouncing frequency and screen hole size.

A kitchen waste resource utilization project uses the TS-1224 bouncing screen, processing 800 tons of mixed waste per day. The separated kitchen waste is pressed and dehydrated before being sent to an anaerobic fermentation system to produce biogas for power generation, while the inert materials are disposed of through harmless landfill. The entire process achieves efficient recycling of kitchen waste. It is important to note that during equipment operation, the uniformity of the feed must be controlled to prevent large impurities from impacting the screen plates and causing damage.

5. Disc Screen: Precision Grading Equipment for Fine-Particle Materials

The disc screen consists of a series of parallel disc shafts. The rotation of the discs propels the material forward and grades it. It is suitable for grading fine-particle materials (e.g., <10mm, 10-20mm) in municipal solid waste, and is particularly adept at handling highly viscous fine materials. It is often used as a pretreatment device for subsequent advanced processing.

Its core advantages are: firstly, high screening accuracy, with the gap between the discs precisely adjustable (1-20mm), and a grading error ≤1mm; secondly, strong anti-adhesion ability, as the shearing force generated by the rotating discs can break up material clumps and prevent blockage; and thirdly, minimal material damage, as the discs are made of elastic material, resulting in a damage rate of less than 5% for easily breakable materials (such as paper and plastic film).

A municipal solid waste composting project uses a DL-1500 disc screen to further classify the <40mm fine material separated by the drum screen. Material <10mm is directly fed into the compost bin, while material of 10-20mm is crushed before composting. Inert matter of 20-40mm is separated and removed, increasing the compost product qualification rate to 92%. Its limitation lies in its relatively small processing capacity (10-50 tons/hour per unit), making it more suitable for small to medium-sized refined processing projects.

6. Key Considerations for Selecting Municipal Solid Waste Screening Equipment

The selection should be based on a comprehensive assessment of the processing scale, material characteristics, processing objectives, and site conditions:

Large-scale projects (daily processing capacity > 500 tons): Prioritize a combination of rotary drum screen and air separator to balance processing capacity and separation efficiency.

Kitchen waste recycling projects: Use a bouncing screen as the core component, supplemented by a disc screen for fine grading.

Small to medium-sized decentralized projects (daily processing capacity 100-500 tons): Choose a vibrating screen or a small rotary drum screen to control equipment investment and floor space.

High-moisture, high-viscosity waste treatment: Prioritize bouncing screens or disc screens to improve clogging resistance.

Recyclable resource recovery projects: Focus on air separators, combined with rotary drum screens to separate light and heavy materials.

The selection of municipal solid waste screening equipment directly affects processing efficiency, resource recovery rate, and subsequent treatment effects. Different types of equipment are suitable for different scenarios: drum screens are the "main equipment" for large-scale processing, vibrating screens are the "economical choice" for small and medium-sized projects, air separators are the "core equipment" for separating light and heavy materials, bouncing screens are the "specialized equipment" for kitchen waste resource recovery, and disc screens are the "precision tool" for fine grading. With the advancement of waste sorting policies and the upgrading of waste resource recovery technologies, future screening equipment will develop towards intelligence (real-time monitoring of screening efficiency and automatic parameter adjustment), integration (integrated screening, crushing, and sorting functions), and environmental protection (low noise and low dust), providing more efficient technical support for the "reduction, harmlessness, and resource recovery" of municipal solid waste.

Save Time! Get A Detailed Quotation Quickly.