PS: In the field of modern industrial ore crushing, cone crusher occupies an irreplaceable key position with its excellent performance and significant advantages. It is widely used in metallurgy, construction, road construction, chemical and silicate industries, and plays an indispensable role in the medium and fine crushing of various ores and bulk materials. Next, let us analyze the characteristics and advantages of cone crusher in depth.

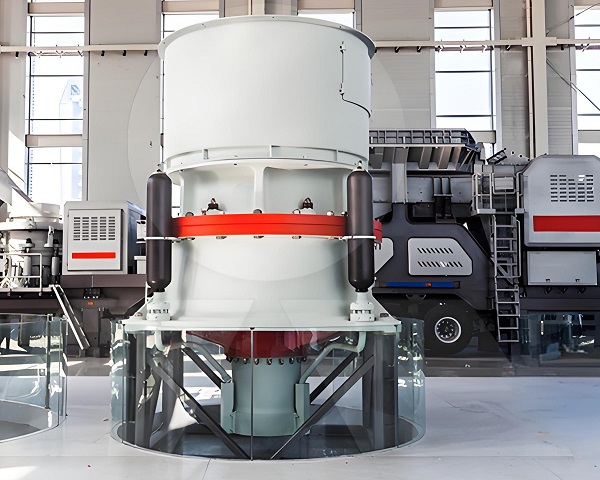

Cone Crusher

A. Working principle and structural basis

The cone crusher is mainly composed of frame, transmission part, eccentric sleeve part, bowl-shaped bearing part, crushing cone part, adjustment device, adjustment sleeve, spring part and lubrication system. Its working principle is based on the extrusion crushing mechanism: the motor drives the eccentric sleeve to rotate through the transmission device, and the axis of the crushing cone performs a pendulum motion under the action of the eccentric sleeve, causing the crushing wall and the mortar wall to move closer and farther from each other. Under the repeated extrusion, impact and bending, the material is gradually crushed into the required particle size. This unique working method lays a solid foundation for the cone crusher to show many excellent characteristics.

B. Excellent crushing capacity

1. High crushing ratio

Cone crushers have the ability to achieve a large crushing ratio, which can efficiently convert larger-sized materials into smaller-sized products. Taking the processing of medium-hardness ores as an example, its crushing ratio can reach 5-8, or even higher. Compared with other types of crushers, under the same feed particle size conditions, the cone crusher produces smaller products, which can better meet the strict requirements of subsequent processing, greatly improve production efficiency, and reduce the pressure of subsequent processing links.

2. Large processing capacity

The design of the cone crusher fully considers the needs of large-scale production and has strong processing capacity. The shape and size of its crushing chamber have been carefully optimized to accommodate a large amount of materials for simultaneous crushing operations. In large-scale mining scenarios, some large cone crushers can process hundreds of tons or even thousands of tons per hour, which can fully meet the high-intensity needs of large-scale production. With the continuous advancement of technology, the new cone crusher has been further optimized and upgraded in structure and parameters, and the processing capacity has been significantly improved, providing strong support for the large-scale development of industrial production.

C. High-quality product particle size

Cone Crusher

1. Uniform particle size

The particle size uniformity of the product after crushing by the cone crusher is excellent, which is one of its significant advantages. During the crushing process, the material is uniformly squeezed and ground in the crushing chamber, making the particle size distribution of the finished product relatively concentrated. Taking the production of sand and gravel for construction as an example, the sand and gravel produced by the cone crusher have uniform particle size, which can better meet the stringent requirements for sand and gravel grading in construction, effectively improve the quality and stability of concrete, and thus improve the overall performance of the building.

2. Regular shape of finished product

The shape of the finished product after crushing by the cone crusher is regular, mostly in the shape of a cube. This feature is closely related to the crushing principle and working method of the cone crusher. The regular shape of the finished product is conducive to the fluidity and filling of the material during subsequent processing and use. In road construction, the use of regular-shaped gravel as aggregate can make the paved road surface smoother and more solid, significantly improving the service life and driving comfort of the road.

D. Efficient operation and maintenance

1. Low energy consumption

Against the backdrop of rising energy costs, the energy consumption of equipment has become a key indicator of concern for enterprises. The cone crusher consumes less energy during operation, thanks to its advanced design concept and efficient transmission system. By optimizing the structure and motion parameters of the eccentric sleeve, energy loss is effectively reduced, so that the energy of the motor can be more efficiently converted into mechanical energy for crushing materials. Compared with traditional crushers, the energy consumption of cone crushers can be reduced by 10% - 20% at the same production capacity, saving enterprises considerable energy costs.

2. Convenient maintenance

The structural design of the cone crusher fully considers the convenience of maintenance. Its various components are reasonably laid out and easy to disassemble and install. For example, the replacement of wearing parts such as the crushing cone and the mortar wall is simple and does not require complex tools and a lot of manpower. In addition, the equipment is equipped with a complete lubrication system and sealing device, which can effectively reduce component wear, extend the service life of the equipment, and reduce maintenance frequency and cost. Some new cone crushers have also introduced intelligent monitoring systems, which can monitor the operating status of the equipment in real time, warn of potential faults in advance, and facilitate maintenance personnel to carry out maintenance in time.

E. Stable operating performance

1. High reliability

During the design and manufacturing process of the cone crusher, high-quality materials and advanced processes are selected to ensure the high reliability of the equipment. Its key components, such as the frame and eccentric sleeve, have high strength and rigidity and can withstand huge crushing force and impact force. In long-term industrial production practice, the cone crusher has shown good stability, and rarely stops due to equipment failure, which provides reliable guarantee for the continuous and stable operation of the production line and strongly supports the normal production of the enterprise.

2. Strong adaptability

The cone crusher has strong adaptability to materials of different properties. Whether it is iron ore and quartz stone with higher hardness, or limestone and gypsum with lower hardness, it can achieve effective crushing. At the same time, it can adapt to different production environments and can still operate stably under harsh conditions such as high temperature, humidity and dust. In some mining sites, the environmental conditions are complex and changeable, but the cone crusher, with its strong adaptability, always maintains a good working condition and meets the production needs.

F. Excellent environmental protection and safety performance

Cone Crusher

1. Good environmental performance

In today's increasingly stringent environmental protection requirements, the cone crusher also performs well in environmental protection. It uses advanced sealing technology and dust treatment devices to effectively reduce the flying of dust during the crushing process and reduce the pollution to the surrounding environment. In addition, its low energy consumption is also in line with the environmental protection concept of energy conservation and emission reduction. In some areas with high environmental protection requirements, the cone crusher has become the preferred crushing equipment due to its good environmental performance.

2. High safety performance

The cone crusher is equipped with complete safety protection devices, such as overload protection and anti-reversal devices. When the equipment encounters an overload situation, the overload protection device will automatically start and stop the equipment from running to avoid damage to the equipment due to overload. The anti-reversal device can prevent the crusher from reversing during operation to ensure the safety of operators and equipment. In addition, the operation interface of the equipment is humanized, the operation is simple and easy to understand, and safety accidents caused by human operation errors are reduced.

PS: Cone crusher has shown strong competitiveness in the field of ore crushing with its excellent crushing capacity, high-quality product particle size, efficient operation and maintenance, stable operation performance, and excellent environmental protection and safety performance. With the continuous advancement and innovation of science and technology, the performance of cone crusher will continue to improve and make greater contributions to the development of industrial production. Whether in large-scale mining or in industries such as building materials production, cone crusher will continue to play an important role and become one of the key equipment to promote the development of the industry.

Save Time! Get A Detailed Quotation Quickly.