Home

About us

Video

Service

Contact Us

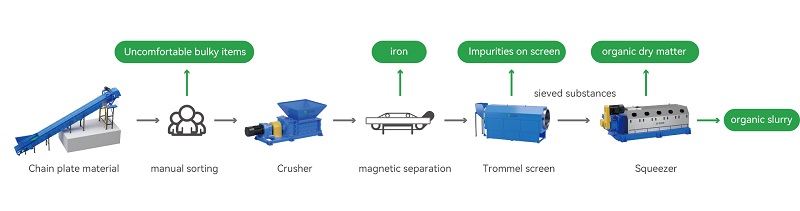

- Construction Waste Screening

- Domestic Waste Screening

- Rotten Garbage Screening

-

Stone Crusher Plant

- 40-60 tph Stone crushing plant

- 80-100 tph hard Stone crusher

- 100 tph Soft Stone Crusher Pla

- 100-150 tph Stone crusher plan

- 180-220tph Stone crushing plan

- 200-300 tph Stone crusher plan

- 350-450 tph stone crusher plan

- 500 tph stone crusher plant

- 800 tph stone crusher plant

- 1000 tph stone crusher plant

- Customer Case

86-18738194110

86-18738194110

86-18738194110

86-18738194110